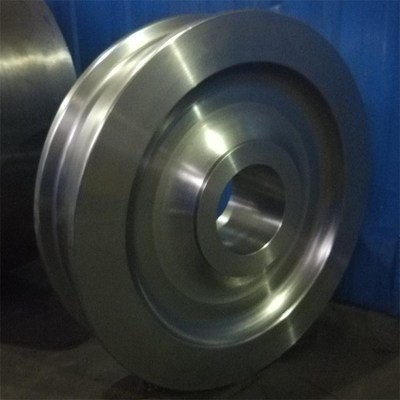

Carbon Steel Forging Wheel

Wheel forgings belong to a type of forgings, the shape of the wheel, usually used in cranes, harvesters, trains, steam turbines, conveyors and other large mechanical equipment. Forgings of high quality, good density, service life growth, large mechanical equipment safety has been better guaranteed. It is the metal that is subjected to pressure, a force typically achieved by the use of a hammer or pressure. The forging process builds fine particle structures and improves the physical properties of the metal. High quality wheel forgings can ensure that magnetic powder, UT ultrasonic, mechanical properties, raw material chemical composition qualified.

Wheel forgings in the 1980s, the general use is cast steel, in the production process due to the casting in the air hole, inclusion, quality instability, safety has hidden trouble. In the process of continuous improvement, the forging is gradually changed to forging. The forging is further refined through heat treatment, surface quenching, hardness enhancement and wear resistance. Heat treatment technology has also been improved, hardness layer depth can also reach more than 20mm.Heat treatment hardness of wheel hot tread: hb320-380

Key projects + high hardness required for export: above HRC40, above HRC50.

The forging is formed by forging the raw materials of iron and steel under the pressure, which can avoid and reduce many defects of the workpiece, and can also retain the linear flow of the metal, which can significantly improve the mechanical properties of the metal material. Integrity with better density and strength. Forgings generally use hot forging to promote crystallization and grain refinement, allowing the material to achieve the maximum possible strength and consistency, and the smallest variation between parts. Forgings generally have high strength, structural integrity, reliability and so on. However, the casting has some defects such as segregation, shrinkage cavity and porosity, which cannot be used in the field of environment and heavy industry. The creep fatigue strength of forgings is more than 3 times higher than that of castings under the condition of large temperature variation

Wheel forgings belong to a type of forgings, the shape of the wheel, usually used in cranes, harvesters, trains, steam turbines, conveyors and other large mechanical equipment. Forgings of high quality, good density, service life growth, large mechanical equipment safety has been better guaranteed. It is the metal that is subjected to pressure, a force typically achieved by the use of a hammer or pressure. The forging process builds fine particle structures and improves the physical properties of the metal. High quality wheel forgings can ensure that magnetic powder, UT ultrasonic, mechanical properties, raw material chemical composition qualified.

Wheel forgings in the 1980s, the general use is cast steel, in the production process due to the casting in the air hole, inclusion, quality instability, safety has hidden trouble. In the process of continuous improvement, the forging is gradually changed to forging. The forging is further refined through heat treatment, surface quenching, hardness enhancement and wear resistance. Heat treatment technology has also been improved, hardness layer depth can also reach more than 20mm.Heat treatment hardness of wheel hot tread: hb320-380

Key projects + high hardness required for export: above HRC40, above HRC50.

The forging is formed by forging the raw materials of iron and steel under the pressure, which can avoid and reduce many defects of the workpiece, and can also retain the linear flow of the metal, which can significantly improve the mechanical properties of the metal material. Integrity with better density and strength. Forgings generally use hot forging to promote crystallization and grain refinement, allowing the material to achieve the maximum possible strength and consistency, and the smallest variation between parts. Forgings generally have high strength, structural integrity, reliability and so on. However, the casting has some defects such as segregation, shrinkage cavity and porosity, which cannot be used in the field of environment and heavy industry. The creep fatigue strength of forgings is more than 3 times higher than that of castings under the condition of large temperature variation