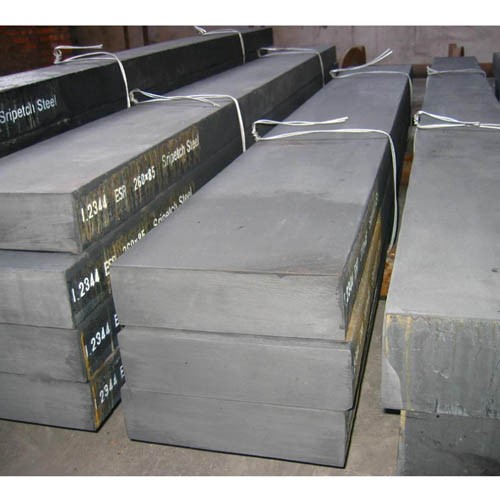

Die Steel Forgings

Die steel forgings

I. product introduction

Die steel is used to produce cold stamping die, hot forging die die casting die steel.Moulds are the main processing tools for manufacturing parts in machinery manufacturing, radio instrumentation, electrical machinery and other industrial sectors.The quality of the mold directly affects the quality of the pressure processing technology, the precision of the product output and production costs, and the quality and service life of the mold in addition to reasonable structural design and processing accuracy, mainly by the mold material and heat treatment.

Ii. Product parameters

Cold working die steel

They were divided into five groups: group W, group O, group A, group D and group S.

◆ W group is water quenched tool steel, there are 11 steel types, 7 carbon tool steel, carbon content from 0.7% to 1.3%.

◆ O group, namely oil quenched die steel (commonly known as oil steel), has 4 types of steel, with carbon content ranging from 0.85% to 1.55%.

◆ group A is air quenched alloy cold working die steel with 9 steel types and carbon content ranging from 0.5% to 2.25%.

◆ D group is high carbon and high chromium cold working die steel, there are 7 steel types, carbon content of 0.9%-2.5%.

◆ S group is impact resistant tool steel, there are 7 steel types, carbon content 0.4%-0.6%.

Also used in cold working die are high speed steel (HSS group) and super high speed steel (SHSS group), cobalt-based carbide and steel bonded carbide (HA group), powder steel and engineering ceramics (PIM group), carbon tungsten tool steel (F group), special purpose tool steel (L group).

Iii. Product advantages

Cold working die steel mostly belongs to hypereutectoid steel and leidelite steel, the hot working and cold working performance is not very good, therefore must strictly control the hot working and cold working process parameters, in order to avoid defects and waste products.On the other hand, by improving the purity of steel, reducing the content of harmful impurities, improve the state of steel structure, in order to improve the hot and cold processing properties of steel, so as to reduce the production cost of the mold.

For improving the cold working die steel performance, since the 1930 S, research to join in steel S, Pb, easy machining element such as Ca, Te or lead to the graphitization of carbon element in steel, developed a variety of free cutting steel, to further improve the cutting performance and grinding performance, reduce tool abrasive consumption, reduce the cost.

Die steel forgings

I. product introduction

Die steel is used to produce cold stamping die, hot forging die die casting die steel.Moulds are the main processing tools for manufacturing parts in machinery manufacturing, radio instrumentation, electrical machinery and other industrial sectors.The quality of the mold directly affects the quality of the pressure processing technology, the precision of the product output and production costs, and the quality and service life of the mold in addition to reasonable structural design and processing accuracy, mainly by the mold material and heat treatment.

Ii. Product parameters

Cold working die steel

They were divided into five groups: group W, group O, group A, group D and group S.

◆ W group is water quenched tool steel, there are 11 steel types, 7 carbon tool steel, carbon content from 0.7% to 1.3%.

◆ O group, namely oil quenched die steel (commonly known as oil steel), has 4 types of steel, with carbon content ranging from 0.85% to 1.55%.

◆ group A is air quenched alloy cold working die steel with 9 steel types and carbon content ranging from 0.5% to 2.25%.

◆ D group is high carbon and high chromium cold working die steel, there are 7 steel types, carbon content of 0.9%-2.5%.

◆ S group is impact resistant tool steel, there are 7 steel types, carbon content 0.4%-0.6%.

Also used in cold working die are high speed steel (HSS group) and super high speed steel (SHSS group), cobalt-based carbide and steel bonded carbide (HA group), powder steel and engineering ceramics (PIM group), carbon tungsten tool steel (F group), special purpose tool steel (L group).

Iii. Product advantages

Cold working die steel mostly belongs to hypereutectoid steel and leidelite steel, the hot working and cold working performance is not very good, therefore must strictly control the hot working and cold working process parameters, in order to avoid defects and waste products.On the other hand, by improving the purity of steel, reducing the content of harmful impurities, improve the state of steel structure, in order to improve the hot and cold processing properties of steel, so as to reduce the production cost of the mold.

For improving the cold working die steel performance, since the 1930 S, research to join in steel S, Pb, easy machining element such as Ca, Te or lead to the graphitization of carbon element in steel, developed a variety of free cutting steel, to further improve the cutting performance and grinding performance, reduce tool abrasive consumption, reduce the cost.