Threaded Flange

Threaded flange

I. product introduction

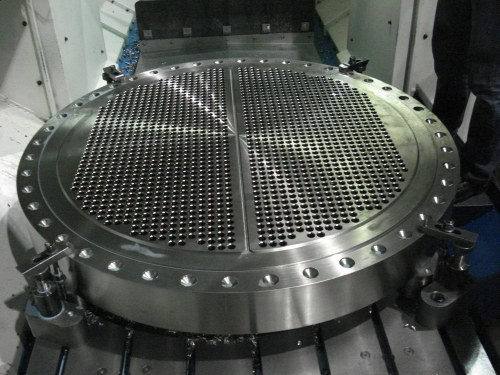

Threaded flange is a kind of flange connected with pipe by thread. When designing, it can be handled according to loose flange. The advantage is that there is no need for welding and the additional torque on the cylinder or pipe when the flange is deformed is very small. The disadvantage is the flange thickness is big, the cost is high. Suitable for connection of high pressure pipeline.

Ii. Product parameters

The size of flange required for installation of different machines is not the same. For this reason, the country in order to unify the standard, determined the standard size of the threaded flange, for different specifications of facilities can be equipped with different sizes of threaded flange. Our country to the regulation of threaded flange includes to its specification, form, dimension parameter made regulation: inside diameter is 48 to 408.6 millimeter differ, range is wider, also accord with the condition that is used extensively so.

Generally, the flange outer diameter is 50-840, and the bolt thickness is 14-52, and the bolt hole spacing is 4-36.

Iii. Product advantages

Threaded flange is the inner hole of the flange is processed into pipe threads and connected with the pipe with threads. It is a kind of non-welded flange. Compared with the flat welding flange or butt welding flange, the threaded flange has the characteristics of easy installation and maintenance. Alloy steel flanges have sufficient strength but are not easy to weld or have poor welding performance.

Threaded flanges can also be selected, but in the pipeline temperature changes sharply or the temperature is higher than 260℃ and lower than -45℃, it is recommended not to use threaded flanges to avoid leakage.

Threaded flange

I. product introduction

Threaded flange is a kind of flange connected with pipe by thread. When designing, it can be handled according to loose flange. The advantage is that there is no need for welding and the additional torque on the cylinder or pipe when the flange is deformed is very small. The disadvantage is the flange thickness is big, the cost is high. Suitable for connection of high pressure pipeline.

Ii. Product parameters

The size of flange required for installation of different machines is not the same. For this reason, the country in order to unify the standard, determined the standard size of the threaded flange, for different specifications of facilities can be equipped with different sizes of threaded flange. Our country to the regulation of threaded flange includes to its specification, form, dimension parameter made regulation: inside diameter is 48 to 408.6 millimeter differ, range is wider, also accord with the condition that is used extensively so.

Generally, the flange outer diameter is 50-840, and the bolt thickness is 14-52, and the bolt hole spacing is 4-36.

Iii. Product advantages

Threaded flange is the inner hole of the flange is processed into pipe threads and connected with the pipe with threads. It is a kind of non-welded flange. Compared with the flat welding flange or butt welding flange, the threaded flange has the characteristics of easy installation and maintenance. Alloy steel flanges have sufficient strength but are not easy to weld or have poor welding performance.

Threaded flanges can also be selected, but in the pipeline temperature changes sharply or the temperature is higher than 260℃ and lower than -45℃, it is recommended not to use threaded flanges to avoid leakage.